Using a mid-length gas system on an M4A1 carbine extends the life of the weapon system and increases the weapon’s performance over a carbine-length gas system, according to a detailed study by Naval Surface Warfare Center — Crane, obtained by Military Times through a Freedom of Information Act request.

The Navy’s Crane center is responsible for testing, evaluating, procuring and managing the life-cycle of U.S. special operations forces’ weapon systems. So, naturally, they tested the mid-length gas system on M4A1 carbines at the behest of Army Special Operations Command.

This study may not come as a complete shock to civilian shooting aficionados and U.S. special operations forces who customize their M4 variants, but it does offer data to back up what those communities have believed for some time.

For the uninitiated, the crux of the issue comes down to when the M4 carbine first replaced the M16 rifle.

In developing the M4, the M16’s gas system was redesigned, according to Crane. The M16 uses a 20-inch barrel and gas system, but the M4 designs were crunched down to fit a 14.5-inch barrel.

Because of the shorter barrel, the gas port was moved down and the dwell distance — the delay between where the bullet passes the gas tube hole to the point where the bullet exits the barrel — decreased.

That decrease in distance from bolt face to gas port on the M4 resulted in an increased port pressure compared to the M16 of the past.

The M4’s port pressure measured at 17,000 psi, while the M16’s was at 10,000 psi.

Many civilian clones of the M4 utilize longer barrels, but also place mid-length gas systems on their custom-built designs. This customization increases the distance from bolt face to gas port than what would be normal on a standard issue M4.

Crane — located in rural Indiana — switched the carbine length gas system on the M4’s 14.5-inch barrel and upper receiver group with the mid-length gas system. Then the study cohort shot 12,600 rounds of M855A1 5.56mm through both designs for comparison testing.

Findings:

The mid-length gas systems experienced a total of 30 malfunctions, while the carbine-length gas systems experienced more than double that at 65 malfunctions. Additionally, the carbine-length gas system suffered 13 unserviceable parts, while the mid-length gas system only suffered 9 unserviceable parts.

[Download the full Mid-Length vs. Carbine-Length Gas System report]

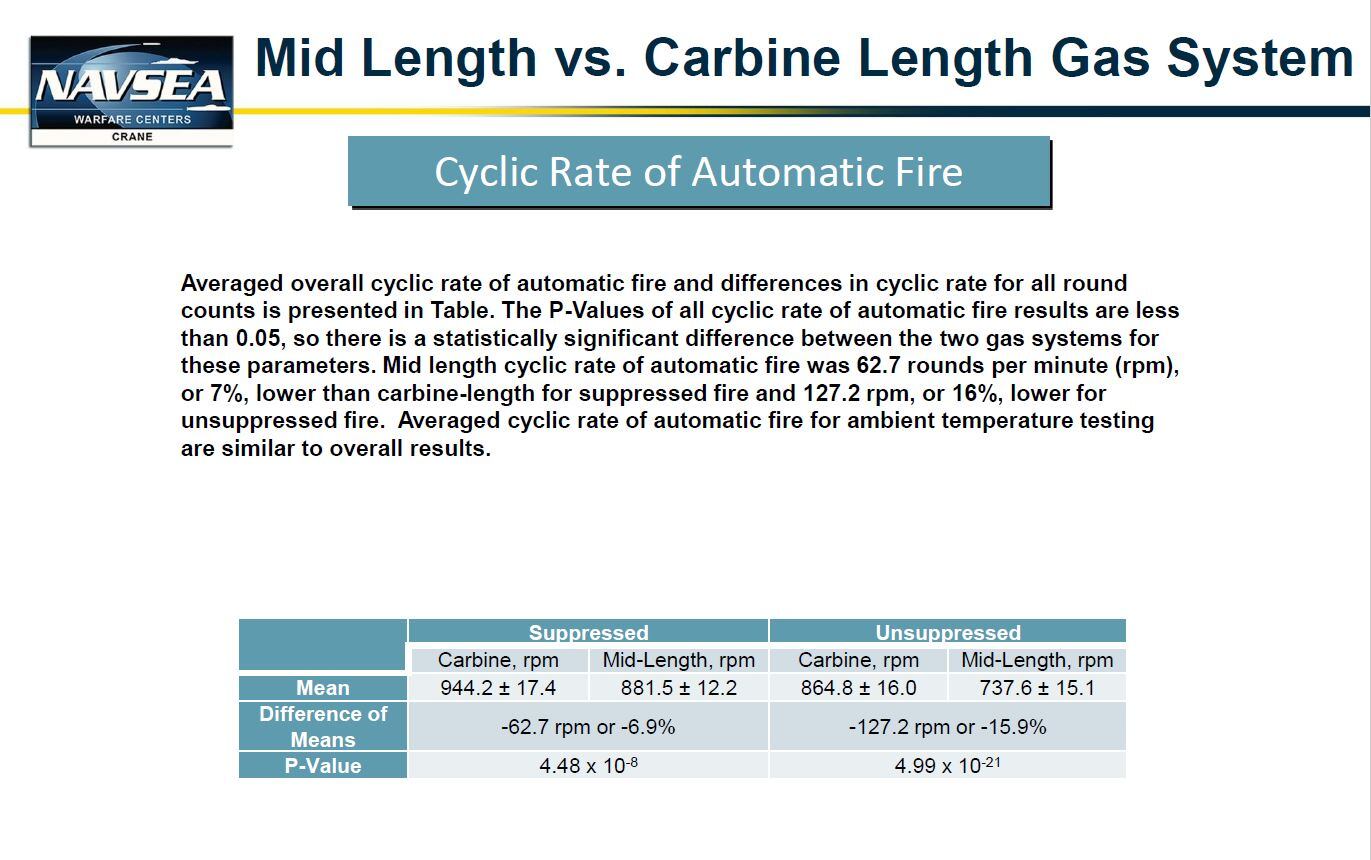

The study also found that the mid-length gas system experienced a decrease in bolt speed and a decreased cyclic rate of automatic fire.

Crane found no statistically significant differences between the two gas system types in terms of weapon precision, barrel erosion, terminal velocity or muzzle velocity. Nor did Crane find any difference in malfunctions or rate of fire between the two gas systems when testing at high and low temperatures, which were 160 and -60 degrees Fahrenheit, respectively.

The Crane study concluded that the mid-length gas system was “recommended for use,” but also decided to continue testing. Crane plans to test the two gas systems up to more than 30,000 rounds.

Kyle Rempfer was an editor and reporter who has covered combat operations, criminal cases, foreign military assistance and training accidents. Before entering journalism, Kyle served in U.S. Air Force Special Tactics and deployed in 2014 to Paktika Province, Afghanistan, and Baghdad, Iraq.